Foshan Yinghao Precision Mould Co., Ltd.

YINGHAO, located in Shunde District, Foshan City, Guangdong Province, is a comprehensive injection mold manufacturer specializing in the production of various types of bottle caps, medical packaging, bottle preform molds and packaging molds. The company has CNC machining center, Shadick, Mazak CNC machine tools, injection molding machines, grinding machines and other advanced machinery production supporting equipment. In terms of quality inspection, we are equipped with various types of secondary projectors, three-dimensional image scanners, hardness testers and other testing equipment to provide customers with high quality and efficient services. We have also established a good communication platform for design and production, so that we can reflect and deal with customers' information in time and fully guarantee the quality and delivery time of products.

View more

FACTORY DISPLAY

Workshop

Workshop

Workshop

Workshop

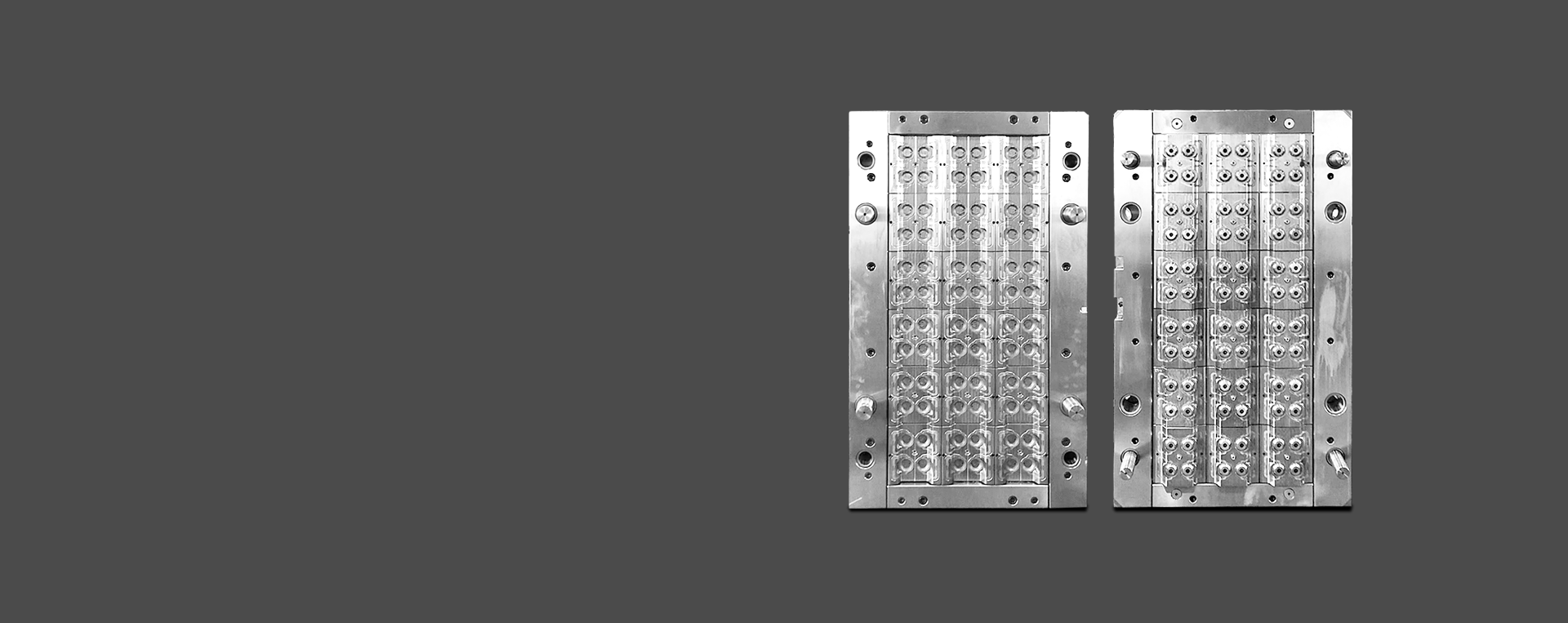

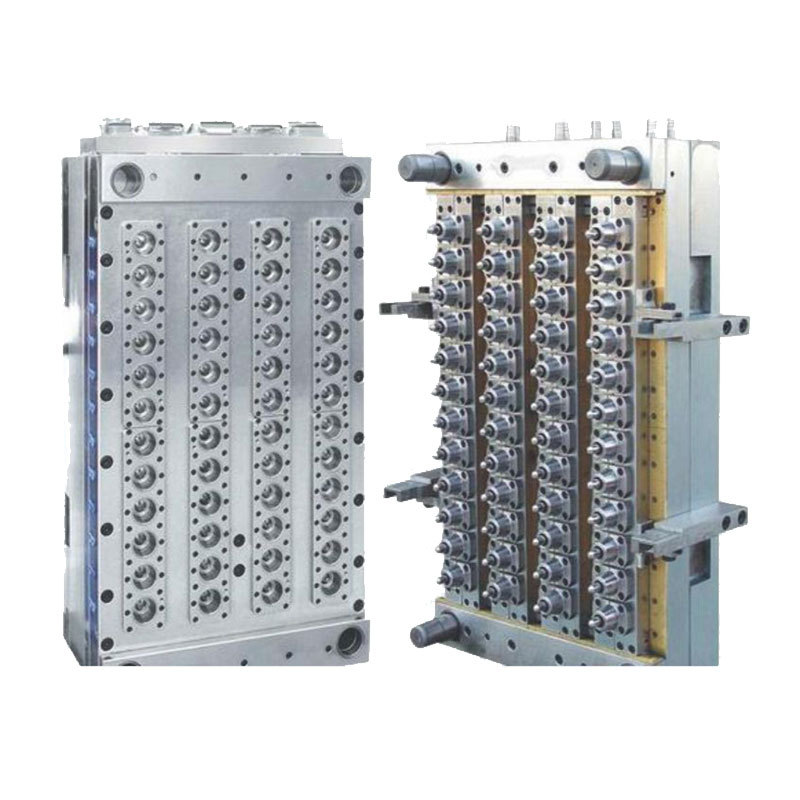

PRODUCT DISPLAY

Specializing in the production of various types of caps, medical packaging, bottle preform molds and packaging molds

NEWS CENTER

Keep up to date with company information and industry dynamics

How the conditions of injection molding production affect the product

Simply put, the complexity of the properties of plastic raw materials determines the complexity of the injection molding production process. The properties of plastic materials are due to different varieties, different injection molding production and processing conditions, different grades, and even different batches. Different injection molding performance parameters can lead to different results View more

How to choose the standard mold base for injection mold processing factory to reduce the processing time

Therefore, in order to make the mold more efficiently, injection mold processors start to use some standard mold blanks. In the custom mold opening, injection mold processors only need to make different molding parts to mold different plastic products, which greatly reduces the time of injection mold processing. So what are the problems that injection mold processors need to pay attention to when choosing the standard mold blanks? View more

Problems easily encountered in plastic molding mold processing

Plastic molding molds are used to produce large quantity injection parts with the advantages of high efficiency, good quality, less cutting, saving energy and raw materials, low cost, etc. However, because of the complex processing of plastic molding molds, many problems will be encountered, and the content of this chapter will introduce the problems easily encountered in the processing of plastic molding molds. 1. Huge size and weight How to cope with the huge size and weight of itself is a big challenge for the plastic molding mold processing factory when processing the plastic molding molds with great volume. The processing of large plastic molding molds often requires a lot of labor, special equipment and multiple set-ups, and the processing accuracy of plastic molding molds is difficult to guarantee due to various potential factors. 2. Expensive purchase cost The cost directly related to the processing and production of various large plastic molding molds is the cost of professional processing equipment. Machine tools that can make large plastic molding molds are very expensive, especially for arranging complex processing processes that require the use of many machine tools to complete the entire process from roughing to finishing. Such a high upfront investment cost is also an obstacle for many companies to enter this market. From here we can see that if we can realize the rough and finish machining of large modulus on suitable machine tools, or even just debug a clamping, then many problems will be solved and the accuracy of plastic molding mold processing can be guaranteed. View more

EFFICIENT AND PROFESSIONAL

360 service system refers to the user-centered, integrated enterprise resources, to provide users with a full range of professional services. The service runs through product development, production, sales and after-sales service.

Pre-sales

——

Customer provides requirements

Research product design

In-sales

——

Product delivery

100% inspection

After-sales

——

After-sales maintenance

PARTNER

We will create a better tomorrow together with advanced equipment, exquisite technology and elaborate service to our customers!

CONTACT US

Add: Room 204, Building 1, Zhifu Baili Industrial Park, No. 28 Nanguo West Road, Daliang Street, Shunde District, Foshan City, Guangdong Province, China